Locations

Innovation and highest quality standards

FLEISCHMANN relies on the highest quality and craftsmanship. The combination of high engineering skills with the precise work of qualified employees distinguishes the detailed models from FLEISCHMANN. More than 900 qualified employees contribute to the success of the FLEISCHMANN brand and work at five company locations. There is also a small shop with selected items at this location, which you are welcome to visit during the following opening hours: Monday to Thursday: 09:00 to 15:00 and Friday 09:00 to 12:00.

PLEASE NOTE: In JULY and AUGUST, our shop closes at 2 p.m. on Mondays and Tuesdays!

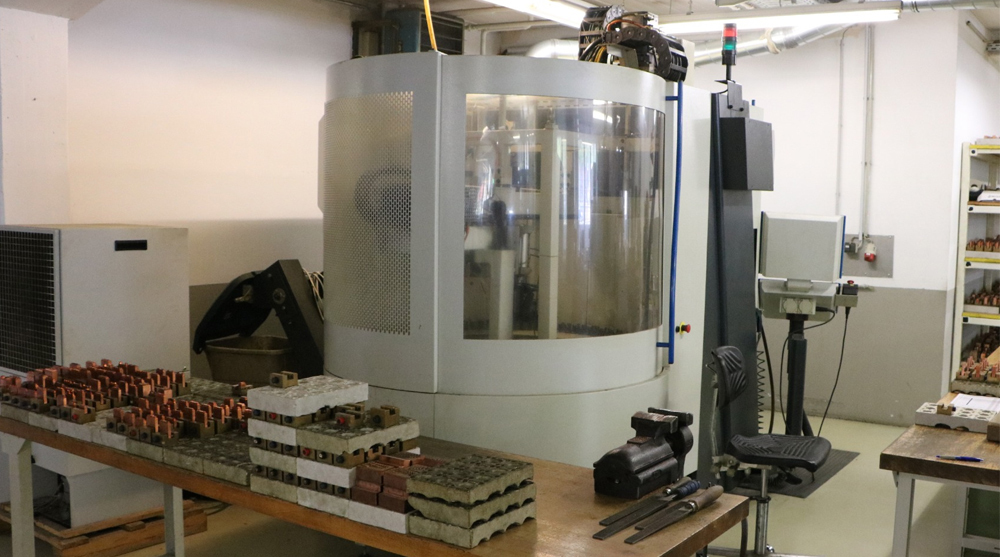

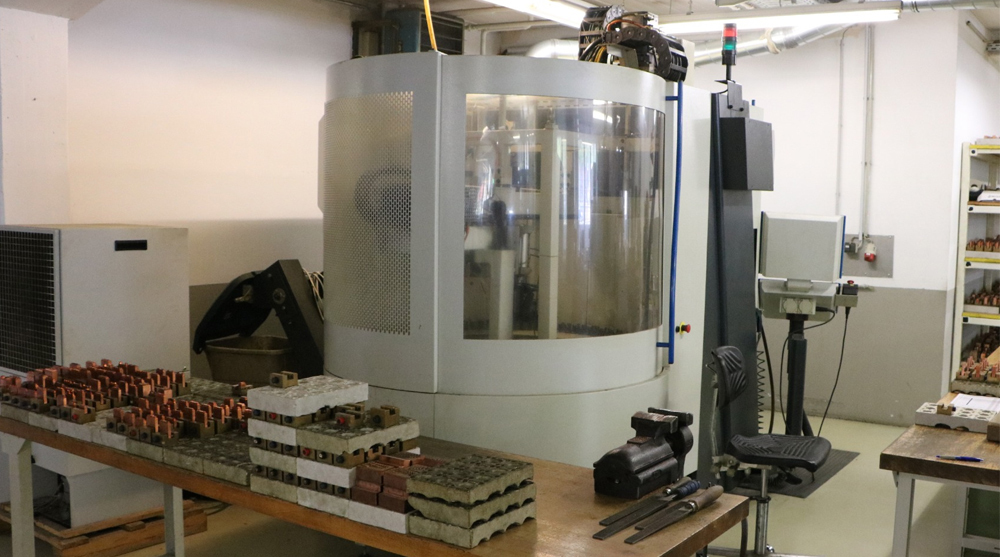

Technikum (technical centre) in Gloggnitz (Austria)

The entire expertise of Modelleisenbahn GmbH in terms of toolmaking is located in Gloggnitz, Lower Austria, from complex housings with multiple sliders to the smallest rivets.

The Gloggnitz plant is also home to the centre for precision plastic injection moulding. Using state-of-the-art precision injection moulding methods and processes, the moulds that make detailed model railway dreams come true are created here.

Production plant in Banská Bystrica (Slovakia)

The Slovakian town of Banská Bystrica is home to the group's most universal plant in terms of its range of tasks. The main location in Banská Bystrica is home to the competence centre for surface finishing, the central production logistics hub and various assembly departments. The surface departments include a paint shop, a large pad printing department with highly functional multi-colour presses and a digital printing department that has become a leader in the industry due to years of research and development. In addition to the surface departments, electric motors for the locomotives are also manufactured at the site, as well as part of the extensive range of rails and accessories using special machines. Metal injection moulding is also located in Banská Bystrica.

The location is complemented by a second smaller production plant north of Banská Bystrica, where a large part of the plastic injection moulding series production, the rail production and the stamping shop are located.

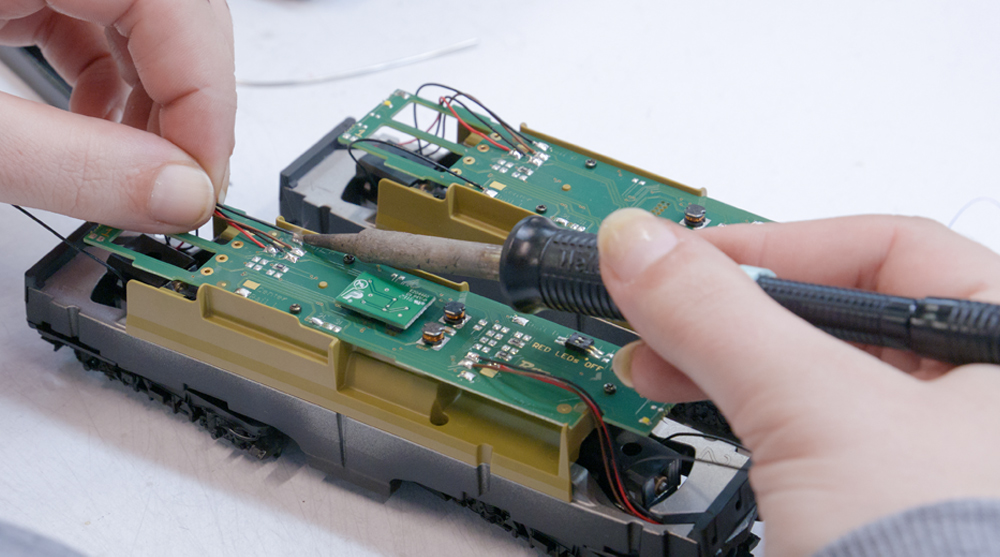

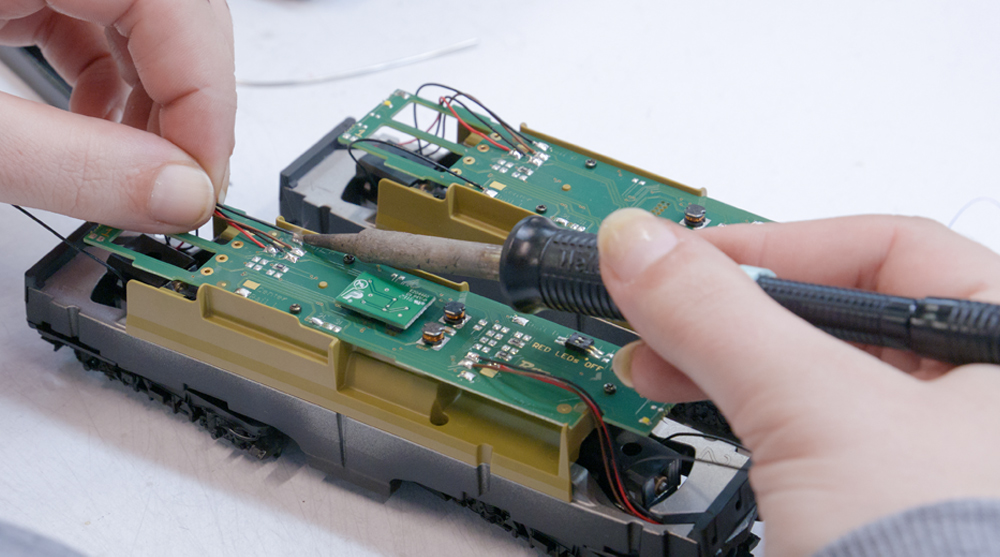

FLEISCHMANN plant in Arad (Romania)

In the modern FLEISCHMANN factory in the Romanian city of Arad, mainly locomotives and a large part of the FLEISCHMANN wagon programme, as well as N-rails (without ballast bed) and the digital components are manufactured. The qualified FLEISCHMANN employees meticulously assemble FLEISCHMANN locomotives and wagons here from several hundred parts, which are then conscientiously tested and subjected to a precise quality inspection. Due to the high quality standards, the FLEISCHMANN factory in Arad was the first factory in the model railway industry to be certified according to ISO 9001 by the German DQS GmbH.

Furthermore, the FLEISCHMANN plant in Arad also houses a small print shop area. The location of Arad, which is considered the industrial centre of Romania and forms an important transport hub in Europe, further distinguishes the ISO certified FLEISCHMANN production site.

FLEISCHMANN Werk in Ho Chi Minh City (Vietnam)

The latest FLEISCHMANN plant is located in Ho Chi Minh City, a city of millions in the economic centre of Vietnam. Since the end of 2016, the wagons from the Start programme and simple locomotives have been manufactured in this state-of-the-art FLEISCHMANN plant. From injection moulding to painting and printing to final assembly, the complete FLEISCHMANN models are produced here. The miniature models are subjected to the same quality controls as in all European factories. This ensures a consistently high standard of quality for FLEISCHMANN model railways worldwide.